Nanostructured Metallic Thermal Interface Technology

Enhancing device reliability, lifespan, and performance through advanced metallic nanostructures.

Nanostructured Metallic Interface

Engineered copper nanocylinders form direct thermal bridges between surfaces. Enables ballistic-level heat transfer far beyond particle-based TIMs redefining the limits of thermal conductivity.

Adaptive Gap-Filling Coating

A polymer composite layer infused with functionalized nanoparticles ensures complete surface conformity and electrical insulation. Eliminates air gaps, minimizes interfacial resistance, and provides stable insulation vital for high-power processors, IGBTs, and MOSFET modules.

Low Resistance

Sustains conductivity above 40 W/m·K under repeated thermal cycling and pressure loads. Outlasts greases, gels, and solders ensuring long-term reliability in power modules and processors. Keeping Rth under 0.15 - 0.17°C/W at 65 °C and above.

Climate-Resilient Design

Functions across extreme humidity, temperature, and dust environments. Ideal for defense, telecom, and industrial electronics where standard materials degrade quickly.

Retrofit-Ready Integration

Available in thin, flexible metallic sheets for direct drop-in replacement. Fits existing heat sink and module designs enabling OEMs to upgrade without redesign.

Smart Manufacturing

Produced through Meerkats’ Vertical Fab Module (VFM) a portable, automated nanofabrication system. Decentralized, IoT-controlled lowers waste and footprint.

CV22 TIM-2

Nanostructured assembly features

Precision-Engineered Nanometal Surface

CV22 is built on a copper interface enhanced with micro- and nano-scale textures that dramatically increase real contact area. This advanced surface architecture enables superior heat spreading and stable long-term thermal performance.

Advanced Polymer-Metal Fusion Layer

A high-performance Polymer-based functional coating is infused into the nanostructured surface, creating a seamless hybrid layer. This unique fusion minimizes gaps and improves thermal flow, resulting in cooler, more reliable electronic devices.

Ultra-Stable Coating Structure

Every CV22 coating undergoes a controlled vacuum treatment that removes trapped air and locks the coating uniformly into the metal surface. The result: a cleaner, smoother, and more durable thermal interface built for demanding environments.

Long-Life Thermal Stability

CV22 is formulated to resist thermal fatigue, oxidation, and mechanical wear. Even after thousands of heating and cooling cycles, it preserves its structure and performance, extending the lifespan of electronics far beyond conventional materials.

Eco-Driven, Low-Waste Design

CV22 is engineered to support sustainability goals by enabling longer-lasting electronics and reducing e-waste. Its durable hybrid interface decreases failure rates, helping organizations meet environmental standards and circular-economy targets.

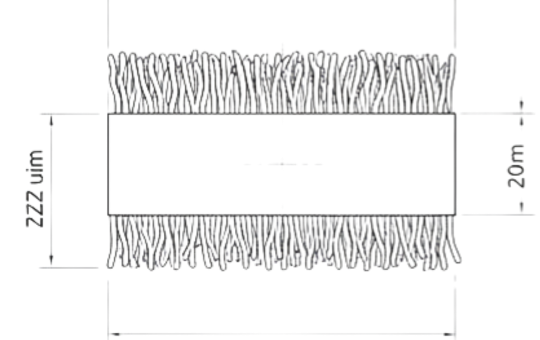

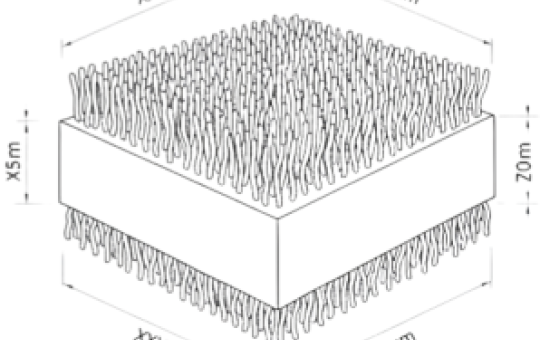

Side View

Isothermal View

ChakraVardhan22

Target Applications

Engineered for high heat-flux, high-reliability electronic systems where conventional thermal interfaces reach their limits.

High-Performance Computing

Servers, workstations, HPC accelerators Thermal interfaces between CPUs, GPUs, and cold plates in data centers and compute clusters.

Power Electronics

IGBTs, SiC MOSFETs, power modules Interfaces in inverters, converters, and high power density switching modules.

Telecom Infrastructure

Base stations, OTN, routers, edge compute Thermal management in 24×7 telecom and networking equipment.

Industrial Electronics

Drives, PLCs, power supplies Long-life industrial systems requiring stable thermal performance over years.

Electric Vehicles & Energy Systems

On-board chargers, traction inverters, BESS High current, high temperature cycling environments in mobility and energy storage.

Defense & Aerospace

Rugged electronics, mission-critical systems Applications requiring mechanical stability and predictable thermal behavior under harsh conditions.

Use Cases

Deployment scenarios where CV22 provides clear technical and lifecycle advantages.

Retrofit Thermal Upgrades

Upgrading existing systems by replacing thermal grease or elastomer pads to reduce interface resistance and slow long-term thermal degradation. Use when: (#1) Field systems show rising operating temperatures (#2) Grease pump-out or dry-out limits lifetime (#3) Downtime and maintenance intervals must be extended

High Power Density Modules

Interfaces in compact power modules where the thermal interface dominates the junction-to-sink thermal budget. Use when: (#1) Heat flux exceeds the stable range of conventional TIMs (#2) Thin bond line control is required (#3) Thermal margin is limited

Long-Life, Low-Maintenance Systems

Applications designed for multi-year operation with minimal service intervention. Use when: (#1) System lifetime > 5–10 years (#2) Maintenance access is limited (#3) Thermal stability over time is more important than initial cost

Warranty-Sensitive Deployments

Situations where reversible, mechanically simple installation is required without electrical or firmware modification. Use when: (#1) Warranty and service compliance is critical (#2) No permanent bonding is acceptable (#3) Standard service procedures must be preserved

Qualification & Benchmarking

Laboratory and pilot deployments to evaluate next-generation thermal interface performance. Use when: (#1) Comparing advanced TIM technologies (#2) Studying long-term thermal stability (#3) Validating junction-to-sink performance improvements