Understanding Heat Spot Formation and the Role of Thermal Interface Materials (TIM)

Research Articles

- Aashish

- Sep 30, 2024

- Research Articles

Understanding Heat Spot Formation and the Role of Thermal Interface Materials (TIM)

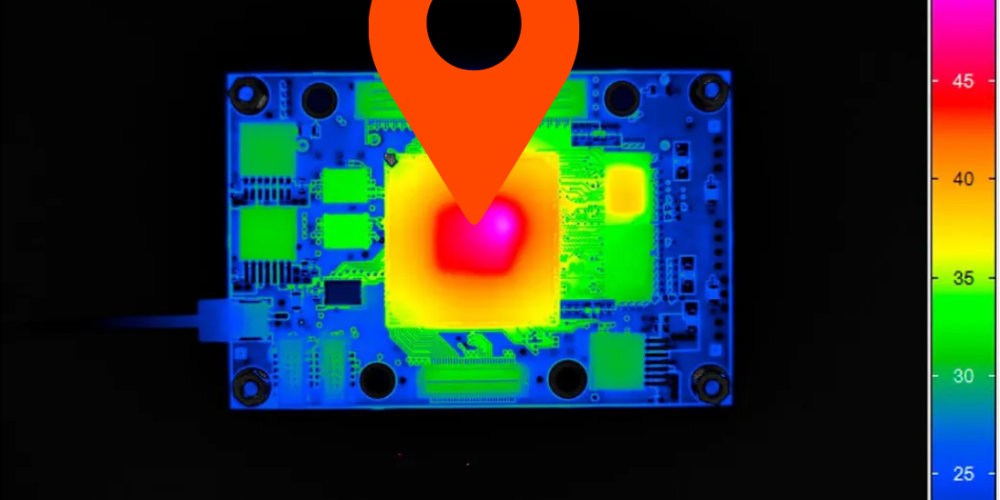

Modern processors, such as CPUs and GPUs, generate significant amounts of heat due to their dense transistor arrangements and high power outputs. One common issue is the formation of heat spots—localized areas where the temperature is much higher than the surrounding regions of the chip. Heat spots are problematic because they affect device performance and reliability, contributing to thermal throttling and even permanent damage if not addressed.

Causes of Heat Spots

The primary cause of heat spots in processors is uneven heat generation across the surface of the chip. Some regions of a CPU or GPU are more active and thus dissipate more heat. This uneven activity leads to localized overheating, where certain areas of the processor surface are much hotter than others. Contributing factors include:

• Power Density Variations: Some areas of the chip are packed with more transistors than others, leading to uneven power dissipation.

• Poor Heat Transfer Paths: Irregular contact between the processor and the cooling system (heat sink) due to surface roughness or improper application of the thermal interface material.

• Aging or Degraded TIM: Over time, some TIMs lose their efficiency due to drying out, cracking, or reduced thermal conductivity, leading to increased thermal resistance and the formation of heat spots.

Consequences of Heat Spots

The presence of heat spots can lead to several problems:

- Thermal Throttling: As the localized temperature rises, processors automatically reduce their operating speeds to protect the chip from damage, significantly affecting performance.

- Electromigration: High temperatures accelerate the wear and tear of conductive materials in the processor, potentially leading to permanent damage or early failure of the component.

- Device Failure: Sustained exposure to excessive temperatures may irreversibly damage the semiconductor material or the transistor structures, resulting in a failed CPU or GPU.

Key Properties of an Effective TIM

To address heat spots, an ideal thermal interface material (TIM) needs to satisfy several critical properties:

- High Thermal Conductivity: This allows the TIM to transfer heat rapidly away from the heat source (processor) to the cooling system (heat sink).

- Mechanical Conformity: A good TIM should ensure full contact between the heat sink and the processor surface by filling microscopic air gaps and voids, which significantly reduces thermal resistance.

- Longevity: TIMs must retain their properties over long periods, resisting drying out, cracking, or performance degradation due to thermal cycling.

- Flexibility: The TIM should adapt to the differences in thermal expansion between the materials it is sandwiched between, especially in scenarios where processors experience varying loads and temperatures.

Do Conventional TIMs Manage Heat Spots Effectively?

While commonly used thermal pastes, gels, and pads provide basic heat dissipation functions, they often fail to address heat spots efficiently. Let’s explore why:

- Thermal Pastes: These are widely used due to their relatively high thermal conductivity, but they are prone to aging. Over time, thermal pastes may dry out or form cracks, leading to the formation of air pockets, which block heat transfer and exacerbate heat spot formation.

- Thermal Pads: These materials are easier to apply but typically offer lower thermal conductivity compared to pastes. They are also less capable of filling the microscopic imperfections between the processor and the heat sink, leading to uneven heat transfer.

Phonon and Electron Scattering in TIMs

Heat transfer in TIMs, particularly in semiconductors, is governed by both phonon scattering and electron scattering. Phonons (quantized vibrations in the atomic lattice) are the primary heat carriers in TIMs. When heat flows through a material, phonons are scattered by defects, grain boundaries, or impurities in the material. In traditional thermal pastes, phonon scattering often occurs due to the lack of uniformity in the paste’s structure, impeding heat flow and creating thermal resistance. In metallic TIMs or advanced nanomaterials, such as vertically aligned metallic nanocylinders, both phonon and electron scattering are minimized. These materials are engineered to have highly efficient heat transfer paths, reducing scattering events that lead to thermal resistance.

Solutions for Heat Spot Management

Advanced solutions, like metallic TIMs or nanostructured thermal interfaces, are specifically designed to handle the challenges of heat spots. For instance, CV22, a nanotechnology-based TIM, features vertically aligned metallic nanocylinders that efficiently transfer heat away from the processor surface, offering superior thermal performance. These nanocylinders create a direct thermal conduit, allowing heat to be transferred rapidly from hot spots to the cooling system.

Unlike traditional TIMs, CV22 maintains consistent contact over long periods and adapts well to the different thermal expansion rates of materials, ensuring better durability and reliability.

In conclusion, heat spots are a significant concern in high-performance processors due to the non-uniform generation and dissipation of heat. While conventional TIMs struggle with long-term efficiency, advanced solutions like nanotechnology-based TIMs provide a more robust and durable option to manage heat spots effectively, improving both performance and lifespan of modern electronic devices.