Understanding Kapitza Resistance and Its Importance in Thermal Interface Development

Research Articles

- Aashish

- Aug 10, 2024

- Research Articles

Understanding Kapitza Resistance and Its Importance in Thermal Interface Development

Kapitza resistance, also known as thermal boundary resistance, is a critical factor in thermal management, especially in the development of high-performance thermal interfaces. This resistance occurs at the interface between two materials and represents the thermal resistance to heat flow across the boundary. It arises from the mismatch in thermal conductivities, phonon transmission, and lattice vibrations between the materials in contact. Understanding and addressing Kapitza resistance is essential for enhancing the efficiency and longevity of electronic devices, and advanced solutions like CV22's vertically aligned nanostructures with proprietary coatings offer innovative solutions to overcome these challenges.

What is Kapitza Resistance?

Kapitza resistance is the thermal resistance encountered at the interface between two different materials, such as a thermal interface material (TIM) and a heat sink. It arises from differences in phonon (heat-carrying vibrations) spectra and lattice mismatches between the materials. This resistance hampers efficient heat transfer and can lead to localized overheating, which adversely affects the performance and reliability of electronic devices. The lower the Kapitza resistance, the better the heat transfer across the interface.

The Concept of Kapitza Resistance

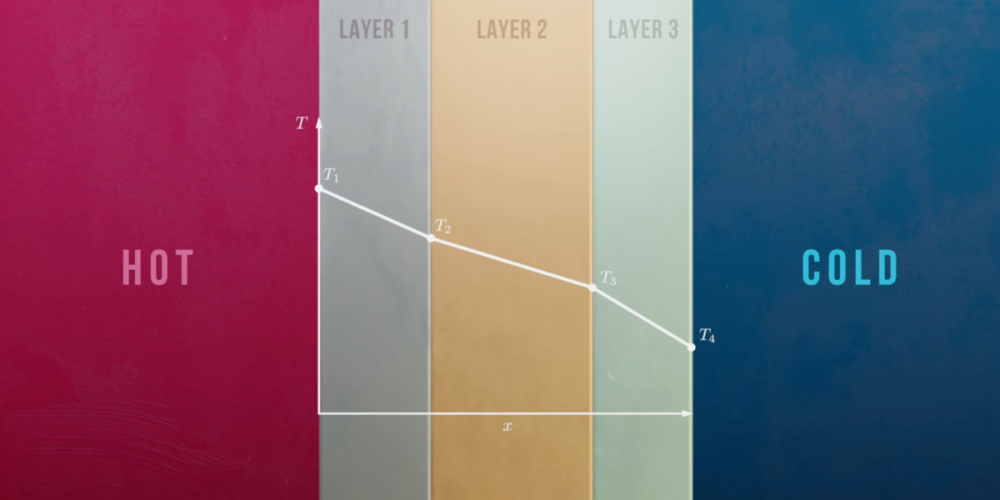

When heat flows from one material to another, such as from a semiconductor to a heat sink, it encounters resistance at the interface. This resistance, termed Kapitza resistance, is particularly significant in systems with differing thermal conductivities. It is quantified by the thermal boundary conductance, which is inversely related to the Kapitza resistance. In simpler terms, high Kapitza resistance means that heat transfer is impeded, leading to inefficient cooling and potential overheating of electronic components.

Several factors contribute to Kapitza resistance:

Material Mismatch: Different materials have different lattice structures and phonon spectra. When heat carriers, like phonons, encounter the boundary between materials with dissimilar structures, their transmission is hindered, causing thermal resistance.

Surface Roughness: The physical roughness of the interface affects how well the materials bond. Poorly matched surfaces can trap heat carriers, increasing resistance.

Phonon Scattering: Phonons are the primary carriers of heat in solids. When they encounter an interface with different acoustic properties, their scattering can significantly impact thermal conduction.

Why is Kapitza Resistance Important?

Addressing Kapitza resistance is crucial for several reasons: Device Longevity: High Kapitza resistance leads to inefficient heat dissipation, which accelerates the aging of electronic components. As devices overheat, their lifespan is reduced, leading to more frequent replacements and increased e-waste. Performance Efficiency: Excessive thermal resistance can cause thermal throttling, where devices reduce their performance to avoid overheating. This affects the overall efficiency and user experience.

Design Challenges: In modern electronics, miniaturization and increased power density exacerbate heat management challenges. Effective thermal interfaces are essential to ensure reliable operation and prevent failure. The CV22 Solution

To tackle the challenges posed by Kapitza resistance, Meerkats.World has developed an innovative solution using vertically aligned nanostructures combined with a proprietary coating. Here’s how CV22’s approach addresses the issue:

Vertically Aligned Nanostructures: CV22 employs vertically aligned nanostructures that provide a continuous pathway for heat flow, reducing thermal boundary resistance. These nanostructures enhance phonon transmission across the interface, facilitating more efficient heat transfer.

Proprietary Coating: The coating applied to these nanostructures improves the adhesion between materials and reduces surface roughness. It also enhances thermal conductivity by optimizing the contact properties at the interface.

Enhanced Performance:The combination of nanostructures and advanced coatings allows CV22’s thermal interface materials to achieve significantly lower Kapitza resistance compared to conventional solutions. This results in better heat dissipation, extended device life, and improved overall performance.

The proprietary coating used in CV22 further optimizes thermal contact by minimizing surface irregularities and improving the wettability of the thermal interface. This innovative approach not only addresses the limitations of conventional thermal materials but also extends the operational life of electronic devices by ensuring efficient heat dissipation.

Call to Action

For developers and engineers focused on thermal management solutions, understanding and mitigating Kapitza resistance is essential for achieving high-performance and reliable electronic devices. CV22 offers a groundbreaking solution with its vertically aligned nanostructures and advanced coating technology, setting a new standard in thermal interface materials. To explore how CV22 can enhance your thermal management strategies and to brainstorm further solutions, please contact Aashish Manocha. His expertise and innovative approach can help you overcome the challenges of Kapitza resistance and optimize your thermal interfaces for better performance and longevity.

Conquer Kapitza Resistance: Elevate Heat Transfer, Enhance Sustainability!!